Inquire Us

Inquire Us

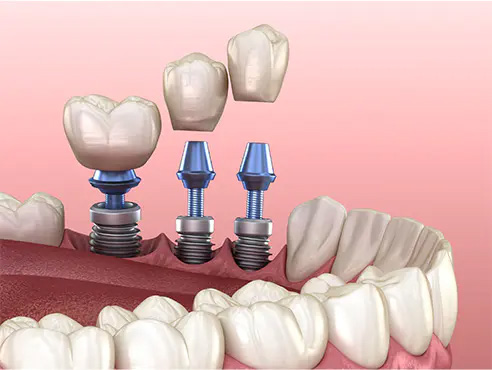

Dental implants made from GR4, commonly used size Ф4.0mm, Ф5.0mm, Ф6.0mm, Ф8.0mm, Ф12.0mm. Dental abutment, fixation nails made from Ti-6Al-4V, Ti-6Al-4V Eli alloy, commonly used size Ф3.0mm, Ф4.0mm, Ф5.0mm, Ф6.0mm, Ф10.0mm. Dental bridge materials using titanium discs, commonly used specifications Ф98 * 12, Ф98 * 14, Ф98 * 16, Ф98 * 18, Ф98 * 20mm.

Our titanium rods, wires and disks have a stable raw material that ensures consistent tensile properties, macrostructure, microstructure and ultrasonic test results. This ensures that all performance indicators meet standards and customer requirements, guaranteeing consistent products.

Dental implants using poor quality titanium alloy material hazards

Titanium wire breakage and difficulties in implant removal can lead to secondary surgeries, increasing the risk of infection and patient discomfort. Additionally, Dental bridge material fractures, poor fatigue resistance, and lack of durability further elevate the risk of infection from secondary surgeries.

Product Advantages:

|

|

|

|

|

|

| High surface finish | Uniform composition | Long fatigue life | Low shrinkage | Good roundness | Fine tolerances |

Company Advantages:

|

|

|

|

|

Full-process independent production |

Super high-quality guarantee |

Professional R&D team with rich experience |

|

Full independent production with high-end equipment for the whole process from melting raw materials to finished products. Ensure that every material can meet standards. |

Certified by ISO13485:2016, and ISO 9001:2015 international quality management system, the company's laboratory is certified by ISO/IEC 17025:2017 |

With our own factory and more than 18 years of experience in the titanium and Nitinol alloy industry, we have an experienced and skilled R&D team and skilled workers. |

|

|

|

|

|

Rigorous testing process |

Strong production capacity |

Support OEM/ODM customization |

|

Our precise testing instruments, effectively remove unqualified products, to ensure that all products fully meet customer's requirements before delivery. |

Our annual production capacity is over 500 tons, we can meet the needs of different customers with different purchase quantities. |

We have a strong R&D team, and we can develop and produce products according to the drawings or samples the customers offer. |

Dental Implant

Dental Implant Systems

Orthodontic Appliances

Dental Vitallium Denture

Titanium Dental Bridge

Titanium Dental Prosthesis